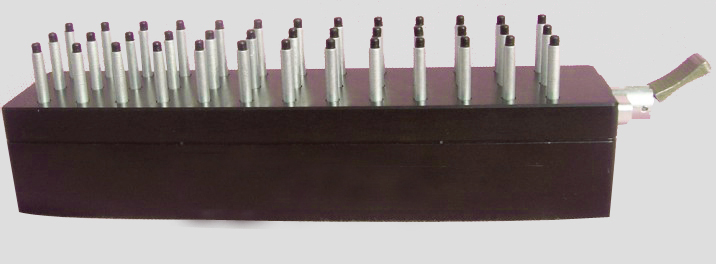

New-style Universal PCB-Supports module is a new product that is specially designed for solving following problems: a large amount of debug time and possible damage to component and PCB microcircuitry caused by hard pin and gauge when using high-density and two-sided PCB to print and mount. The PCB-Supports module can help you solve printing press and chip mounter's problem of touching the board. Anyone can use this product handily.

Product advantageous:

1. Easy operation: directly put the pin module into two guide rails. PCB need no precise alignment.

2. Increase efficiency: saving more time when changing wires than using original hard PIN.

3. Good generality: applying to any PCB and any brand of printing press.

4. Safe and reliable: avoiding damages to component and microcircuitry caused by inaccurate alignment.

5. Durability: adopting precision mechanical principle. Guaranteeing 2 to 3 years’s srvice life under normal operation.

Technical parameters:

1. External dimension: length 200mm × width 42mm (standard size). We can customize different sizes according to customer’s different needs.

2. Anti-static parameters: below 1000MΩ.

Applied to :

1. All printing presses in the market, eg. DEK、MPM、PANA、EKRA、YAMAHA、HITACHI、GKG、DESEN

2. All kinds of chip mounters, eg. PANASONIC、FUJI、SIEMENS、JUKI、YAMAHA、SAMSUNG、PHILIPS、SONY、SANYO

Operating instructions:

1. First, put the pin module on the supporting platform of printing press. Decide the quantity of pin module according to the size of PCB. PCB enters into the platform of the printing press through the track, meanwhile, the platform rises.

2. If the pin touches PCB, the pin of component will go down automatically. Then, lock the pin module. So the pin will form a shape similar to gauge according to the distribution of PCB component.

3. We can see the overall distribution of pins after we remove PCB.

4. Later, if using the same PCB to print, PCB can be directly conveyed to platform through the track. Then the fixed pin module touches PCB to start printing.

5. If wires need to be changed, we just need loosen lever of the pin module and repeat the first step. It takes about 30 to 150min when using original hard PIN to change wires, but now it takes less than 10sec by using the pin module. |